Arduino Consulting and

Development

Specializing in Arduino, Robotics, and

Control Systems

Feldman Consulting Enterprises,

LLC

![]()

| Main | Arduino Consulting | Instrumentation Design | Wireless Networks | What Sets Us Apart | Background | About Us |

|

Feldman Consulting Enterprises, LLC is one of the most well-known consulting firms for Arduino and robotics engineering projects. We can ensure that your project will be a success!

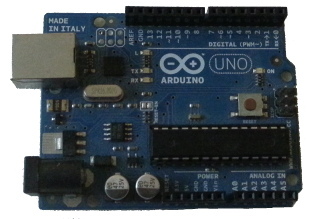

Robotics / Arduino boards You may not even be aware that your project might be able to benefit from the latest robotic upgrades and enhancements, such as the Arduino platform. With robotics boards and microprocessors becoming more common and less expensive incorporating the latest robotic technology into your designs can reduce cost by replacing many different components and add functionality that you never thought possible! Several projects have been designed to take advantage of the capabilities of Arduino boards and custom-designed shields.

An Arduino board is a low-cost open-source electronics board with its own programmable microcontroller that makes it easy to communicate with computers and sensors, and to control things like motors, servos, and relays. The possibilities are endless!

What can an Arduino board and robotics do for you?

You can even have a wireless sensor or remote control network! Here's how we can help. Feldman Consulting Enterprises, LLC has experience engineering Arduino-based solutions involving wireless communication, Wifi, and Bluetooth, sensors, cellular communication, motor control, sophisticated control systems, and data storage. In addition we have relationships with suppliers who work with machining, sheet metal, 3D printing, and production of electronics boards to carry projects from concept to full production. We were one of the first consulting firms to get involved with using the Arduino for commercial products and have taken advantage of the capabilities of these boards to deliver superior results for our clients including cost reduction, customization, ease of assembly, and durability improvements. Our projects have been deployed all around the world!

Are you considering a PLC (Programmable Logic Controller)? PLCs are commonly used in industrial and manufacturing environments to control and monitor electronic systems. When should you consider an Arduino over a PLC?

PLCs have several advantages over the Arduino.

However, the Arduino has several advantages over the PLC.

Is the Arduino as reliable as a PLC? The short answer to that is yes. There are many electronic devices produced very inexpensively that run reliably for years - including common consumer items like phones, microwaves, calculators, and clocks. The Arduino is based on the industry-standard and proven Atmel AVR microcontroller. While the PLC is technically designed to be tougher and handle harsh environments, this is overkill for most situations that a control system encounters and that doesn't make a PLC more reliable than an Arduino outside those situations - and there are things that can be done to toughen up the Arduino if necessary. Sensors and communications base stations that we designed using the Arduino have run for weeks at a time. And we've made sophisticated laboratory equipment based on the Arduino that is sold around the world!

Typical types of problems we've solved:

Ask yourself:

Did you answer "yes" to any of the above questions? We can help!

Here's how we've helped other clients harness the power of Arduino. You could be next!

Case One - A Better Way to Seal Ampules A local company desired to improve upon an ampule-sealing device that they were selling by developing the next generation of their product. By listening to their customers they knew what types of characteristics and features would be necessary to ensure that the redesign would be a success. The redesign involved improving the reliability and durability by replacing many mechanical components with electronics and sensors in conjunction with an Arduino robotics board and a custom-designed shield, which allowed for customer-requested adjustments to be made while using the device, such as speed and timing control. Any parts that were wear items were designed to be easily replaceable and many wear items were completely eliminated. Other attributes that were important to the customers such as noise and ease of adjustment were also addressed. In addition the modular design of the updated device allowed for flexibility in manufacturing and future product development. The building of subassemblies could be contracted out and assembly was simplified, reducing the amount of labor and lead times necessary to build the device. The system was also designed to accommodate add-on modules (which also use Arduino boards) so that it would be easy to expand the device to handle additional needs that customers had, including gas purging and liquid filling of ampules. Through clever engineering both add-on modules were designed to have commonality of over 80% of the parts, reducing development time and costs, and simplifying production. By developing these add-on modules the company was able to serve a segment of the market that previously was unable to automatically fill ampules, which made the device very popular among their customers. With the improvements and additional capabilities of the product line the company is also able to target new markets and applications, further increasing the potential for sales. Results:

See the Ampule Sealer in action!

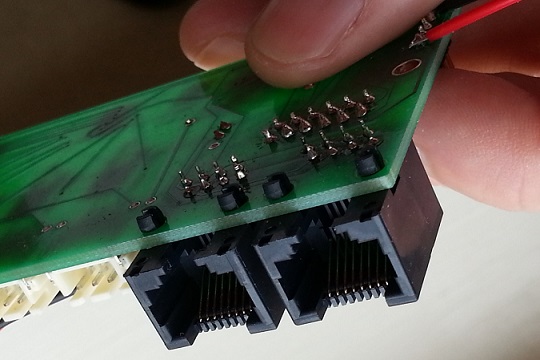

Case Two - Major Overhaul of Electronic Locker Rental System A company in the electronic locker rental business was having major problems with the control boards on their rental lockers. The boards were extremely unreliable, with many complicated mechanical components that frequently got out of adjustment and design decisions that resulted in communication problems and fried components that would often result in entire banks of lockers being inaccessible. This was costing the company significant amounts not only in the cost to maintain and repair these lockers but in reputation with their business partners who could very easily choose to sign contracts with competitors. To complicate matters the client needed any new control boards to be backwards-compatible with their current control kiosks as they had many of these out in the field and wouldn't be able to replace them all. An overhaul of the control boards for the lockers was long overdue. Sophisticated mechanical components were replaced with very reliable off-the-shelf locking mechanisms to reduce complexity of the control boards. An Arduino-compatible processor was used on each of the boards to handle the communication with the existing kiosks and allow for advanced electronic troubleshooting and diagnostics to aid in fixing any problems that might arise. Using an Arduino-based system also allowed for much easier firmware updates when new features were necessary. Domestic suppliers were able to be used for the control boards instead of the overseas suppliers that were previously used, reducing inventory costs and lead times significantly while increasing quality. But one of the largest benefits was that the new control boards were able to control multiple locks, significantly reducing the cost of the parts and eliminating a large amount of wiring, in addition to reducing maintenance costs. A staged approach to the development allowed for changes to be made in the boards and testing to be done on a small run of prototype boards while reducing risk to the client because this project needed to be completed extremely quickly so that hundreds of boards would be ready for installation of new lockers in time for the peak locker rental demand season. Results:

Even including the development and testing costs for the design of the new boards, the first installation actually cost significantly less than it would have with the previous boards

Case Three - Hoist Rope Tilt Sensors A client had a problem with ropes on hoists being raised when the ropes were too far from vertical. This not only caused dangerous situations where loads could shift and swing when hoisted, potentially injuring bystanders, but also contributed to excess wear on the drive units of the hoists and also broke hoist ropes, which incurred downtime in production facilities and extra costs to replace the broken ropes. The client needed an add-on device that could be integrated into the current design of the hoist control systems to prevent the hoist from operating when the angle of the ropes was too great. An Arduino-based PCB was designed that controlled several relays based on the angle of the rope to ensure that the hoist could only be operated in a manner that minimized the amount of tilt to reduce the problems incurred during operation while minimizing any impacts of use of the hoists on production. Results:

An Arduino-based control system improves safety and reliability by ensuring the hoist ropes are close to vertical.

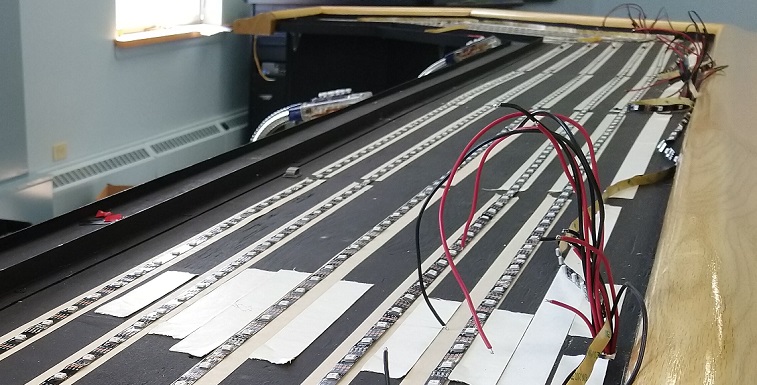

Case Four - LED Strip Light Display for a Bar A local community college was building a bar for their bartending training program. But they didn't want just an ordinary bar - they wanted something special to make their bar stand out. An Arduino-based controller was designed to manage multiple LED strips and allow individual pixels to be controlled on each one, making for a completely customizable and very special bar! Results:

Thanks to Arduino-controlled LED strips this is a bar with a unique twist!

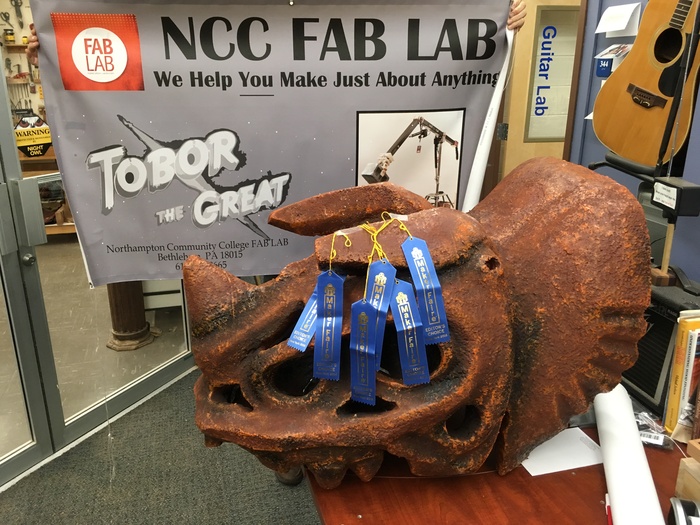

Case Five - TOBOR, the Giant Robotic Dinosaur TOBOR was developed to showcase the many different talents of the people at the Northampton Community College Fab Lab in Bethlehem, PA. The project featured machining, woodworking, 3D printing, resin casting, wireless communication, audio engineering, and robotics all combined together in a 6-foot robotic dinosaur controlled by a glove with haptic feedback. Feldman Consulting Enterprises, LLC served as the lead for the robotics engineering. This involved specifying the robotic and electronic components and developing the software and wireless interfaces between all the different components. TOBOR was a combination of the efforts of many people at the Fab Lab and was exhibited at the Maker Faires in the Bay Area in 2015 and in New York in 2015 and 2016. At the 2016 World Maker Faire in New York TOBOR won 6 Editor's Choice awards and was chosen as the #2 Coolest Project At Maker Faire by PCMag. Going forward it will serve as a teaching tool for the lab and will be displayed at future Maker Faires and events around the nation.

TOBOR was exhibited at the Maker Faire in the Bay Area in 2015, 2017, and 2019, and in New York in 2015 - 2018.

Case Six - Escape Room Games Escape Room games with themed scenarios containing multiple puzzles for participants to solve have been increasing in popularity. But many of the franchises and storylines that are purchased don't contain the necessary electronics to power the puzzles. Feldman Consulting Enterprises, LLC has developed a robust solution to handle multiple RFID readers, and interface with many other components such as magnetic door locks, solenoids, and keypads. The printed circuit boards developed greatly reduce the number of connections and wiring and simplify long routing runs through walls and ceilings. In addition, the code for the Arduino is highly flexible and easy to modify, making it very easy to customize for a variety of puzzles and challenges - making it easy to upgrade and update the games to keep customers returning! Results:

A themed room full of puzzles to solve makes Escape Room games lots of fun!

Case Seven - Arduino PLC Replacement for a Powder Dispenser A client bought out the remnants of a product line for a powder-dispensing device that used a traditional PLC. Upon assessing the situation for manufacturing this product in the future it was determined that the incredible complexity of the wiring would make these very difficult to put together. Furthermore, the design of the system used components that were unnecessarily complicated and expensive. By replacing the PLC with a custom-designed PCB incorporating an Arduino the amount of wiring was greatly reduced and the client is now able to order fully-assembled boards from suppliers in the US, which simplifies manufacturing immensely. A very expensive external thermostat was replaced with a much simpler thermistor and relay on the board to control the heater. A nice color screen was also added to make it easier for the end users to see how their equipment is operating. Fault detection capabilities were also added to the controller. The cost of the fully-assembled boards ended up being less expensive than the original PLC in addition to the savings gained from simplifying other parts of the system and the reduced assembly complexity. Results:

Everything is easy to connect and the major components are easy to replace.

Feldman Consulting Enterprises, LLC has also worked on smaller Arduino projects including general troubleshooting, sensor connections, wireless communication, shield design, and timing issues. We're a leading provider of Arduino and robotics engineering services. If you need an Arduino expert - you've found the right place!

Are you interested in Arduino wireless networks? See some of the possibilities here! We also specailize in Instrumentation Design

Brian Feldman's answers to Arduino questions on Quora:

Your project could be a Breakthrough! Contact us today to find out how! Feldman Consulting Enterprises, LLC has worked with clients all over the world and is based out of Macungie, PA. Phone: 484-695-5651

(c) 2025 Feldman Consulting Enterprises, LLC |