Arduino Instrumentation

Design

Specializing in Arduino, Robotics, and

Control Systems

Feldman Consulting Enterprises,

LLC

![]()

| Main | Arduino Consulting | Instrumentation Design | Wireless Networks | What Sets Us Apart | Background | About Us |

|

Feldman Consulting Enterprises, LLC can help you design precision instrumentation using the Arduino platform, including feature-rich touchscreens, interfacing with specialty sensors, and data logging.

Instrumentation Design We have designed many specialized instruments for different industries that involve working with unique sensors and providing user-friendly interfaces that make the instruments very easy to use. Some clients use instrumentation for internal testing or servicing, while others sell instruments through their industry as high-margin products, and there are also clients who use instruments for purposes of product differentiation to enhance their existing offerings. If you need to be able to work with sensors that are very specialized, the Arduino can communicate over many different standards, such as RS232, RS485, Ethernet, and Serial communication. The Arduino can also be programmed to use the custom commands that are often necessary to interface with these sensors. In addition, if there certain items that need to be controlled to appropriately take readings or be managed based on the readings taken, the Arduino can operate and adjust many types of equipment as well, including solenoids, valves, and relays. We can even control systems that require DC voltage input, frequency, or 4-20 mA signals. Some instruments are used for showing data immediately on a screen, while others need to log data to an SD card or database over time, or transmit it over Bluetooth to a computer or tablet for further processing. Here's how we've helped other clients design instrumentation systems using the Arduino.

Case One - Nitrogen Monitoring System for Advanced Septic System Nitrogen Sensor Challenge A professor at Stony Brook University had developed technology for monitoring nitrogen levels in advanced septic systems and needed to build a prototype unit for a 6-month field verification test with the EPA in order to demonstrate the performance of the technology and take the necessary steps to bring the technology closer to commercialization. We developed a control system to allow for very inexpensive components to be used for microdosing fluids and reporting data in realtime to a SQL database for monitoring the measurements taken by the system and recording a complete history of the operation of the units throughout the test. This system won the Advanced Septic System Nitrogen Sensor Challenge! VerifiGlobal has issued a Verification Statement of the performance. Results:

The Verification Statement for the performane of the Nitrogen Sensor is now available.

Case Two - Heating Pad Temperature Control System A medical device manufacturer needed a temperature control system for their unique heating pads, which were used for therapeutic applications. The device needed to be easy to use, featuring a touchscreen and control knobs to adjust the settings, including different time and temperature profiles for therapy applications. In addition, being used for medical purposes, the device needed to be designed with multiple safety features and failsafes built in to ensure that the device was always functioning as intended and was always able to quickly shut itself down if a fault were detected. Results:

Heating Pad Control System

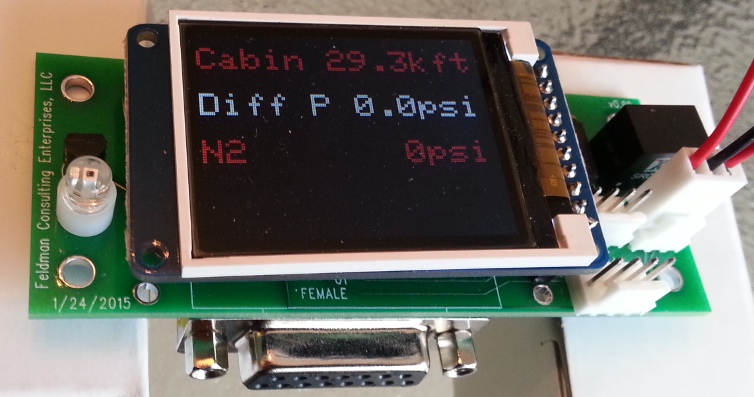

Case Three - Aircraft Sensor Display Board A high-end aircraft manufacturer needed to have several different pressure sensors read and displayed so that they would be able to deliver the aircraft to their customers. We developed a custom printed circuit board for ease of assembly and the robustness necessary to deal with the temperature variation and vibrations encountered within aircraft. The display was driven by an Arduino Pro Mini and the code was developed to make calibration and configuration of the outputs very straightforward. All the necessary power and sensor connections were routed through one DB15 connector for easy hookup inside the aircraft. Results:

This board will display readings for several aircraft sensors.

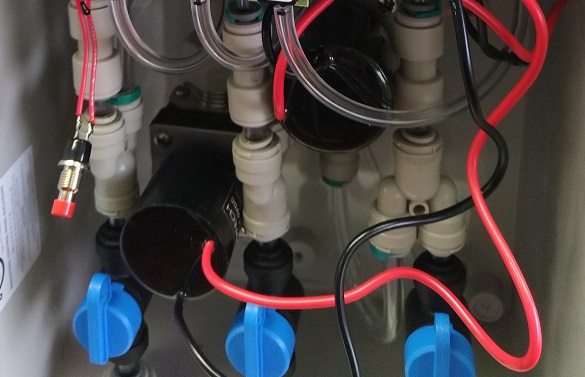

Case Four - Pressure Monitoring for Piping Systems A manufacturer of piping systems wanted to have monitoring capabilities for the systems they provided as a tool to differentiate their product from competitors and to be able to assess system performance over time. The monitoring required not only measuring pressure in several different lines, but also controlling valving to ensure that lines were cleared out as necessary prior to performing the measurements. Initially the instrument was designed to be placed outdoors for long periods of time relying on battery power only, but a derivative unit was also desired that was more portable and could take readings at many different points throughout a system. The demands for both of these units were able to be met with a single PCB design that allowed for the specific components necessary to meet the needs of each system. Results:

This pressure monitoring system controls necessary valving and solenoids to take appropriate measurements.

Case Five - Complete Redesign of a Laboratory Instrument A client had a major laboratory instrument that had last been designed approximately 20 years prior. The instrument was designed to connect with a PC for data collection. There were several problems that needed to be addressed with the design. Many key components were now obsolete and getting increasingly difficult to find, and others were rapidly increasing in price. The parallel interface to the computer was also quickly becoming obsolete and difficult to support. And among other issues, the motors that were used in the instrument generated a lot of heat, were difficult to control, and were prone to failure. Since a lot of the customers for this instrument were international it was also important that this unit be able to operate on non-US power. A complete engineering redesign was undertaken to address all the issues. The proprietary power supply was swapped for more commonly-available power supplies that met an industry standard for ensuring good power quality and support for non-US voltages. The motors were replaced with a much newer and less expensive technology that reduced the heat generation by over 90% and allowed for much more precise control. The temperature controller, which consisted of a resistance heater and refrigeration loop, was replaced with several thermoelectric modules for scalability, reliability, more precise control, and cost reduction. An Arduino Mega robotics board was programmed to control the entire system, integrate self-diagnostics, take advantage of the latest available sensors, and allow for USB communication and data collection with a PC into an Access, mySQL, or MSSQL database. A special shield was developed to integrate with the Arduino board to handle all the wiring connections and sensors. By taking an overall view of the system the redesign was able to make every system significantly better than its predecessor and the instrument as a whole was able to combine and share components to reduce cost in a way that was not possible before and to not only copy what the competition was offering, but leave them in the dust. Results:

This is a prototype shield developed for the Arduino robotics board that interfaces with all of the necessary sensors and controllers and all eight reactors.

Case Six - Precision Alignment Instrumentation for Turbomachinery A consultant in a very unique industry performed alignments for gigantic shafts in turbomachinery, requiring the precise measurement of both angles and shaft runout. Not only was the consultant interested in having instrumentation designed for his own use to replace mechanical methods that required a lot of calculation, but he saw an opportunity to sell these instruments to others throughout his industry. An Arduino-based solution was developed that had a touchscreen interface and minimized wiring connections between the main interface and remote sensing units, making it easy for operators to use. The devices were designed with remote interfaces to allow operators to control the instruments from more convenient locations. Bluetooth was integrated to automate data transfer to proprietary computer software to make the necessary calculations to perform the shaft alignments properly. Results:

Case Seven - Arduino Control Systems for Coronavirus Ventilators and Respirators Multiple companies have contacted Feldman Consulting Enterprises about creating control systems for ventilators and respirators in response to the coronavirus pandemic. While there are existing designs out on the market, certain factors such as time-to-market and availability of parts have led to the design of several new prototypes to meet these ever-changing needs. Feldman Consulting Enterprises responded by providing extremely quick turnaround on these time-critical projcets. The designs were made the ability to accommodate the addition of other potential sensors and actuators to reduce the need to build entirely new hardware for potential revisions in the future, saving even more time and expense. The Arduino platform has also been suggested for other critical medical equipment where affordability and serviceability are major concerns. Results:

Arduino can help in critical situations.

Feldman Consulting Enterprises, LLC can develop your Arduino-based solution involving instrumentation design !

Arduino Robotics Consulting

Your project could be a Breakthrough! Contact us today to find out how! Feldman Consulting Enterprises, LLC has worked with clients all over the world and is based out of Macungie, PA. Phone: 484-695-5651

(c) 2025 Feldman Consulting Enterprises, LLC |