Arduino Wireless Networks

Specializing in Arduino, Robotics, and

Control Systems

Feldman Consulting Enterprises,

LLC

![]()

| Main | Arduino Consulting | Instrumentation Design | Wireless Networks | What Sets Us Apart | Background | About Us |

|

Feldman Consulting Enterprises, LLC can help you take advantage of the possibilities of wireless communication with Arduino, including data collection, monitoring, and remote control.

Wireless Data Collection and Monitoring We can design and implement systems based on Arduino and Xbee for data acquisition from large areas, such as an entire facility or a large field. You can use this data to monitor your own operations in real-time, track historical trends, or even aggregate data from your customers and provide it back to them. The Xbee wireless transmitters have ranges from several hundred feet indoors to several miles in line-of-sight conditions outdoors with appropriate antennas, which allow for construction of incredibly large mesh networks and SCADA systems! Your information can be sent to secure databases on the Internet through a standard Internet connection, or through a cellular connection for more remote or difficult locations. The data can be bundled from multiple sources and sent through one connection to the Internet, reducing your infrastructure and communication costs. We have designed sensors that provide real-time data where power is available, and also have designed low power sensors that send data once every few hours but can run for 3 years without requiring a battery replacement. Our sensors are designed to be tough enough for outdoor use with industry-standard NEMA boxes and have proven themselves in temperatures as low as 0F / -18C, as high as 100F / 38C, rain storms, and snow storms!

Arduino Wifi - The Arduino can be connected to the Internet over 802.11 b/g/n using the same routers and access points that are set up for computers, laptops, and mobile phones. Arduino Bluetooth - Bluetooth and other similar wireless protocols can be used between Arduino-based nodes to aggregate data or to interface with mobile phones. Arduino Xbee - By using Xbee 802.15.4 technology, a large mesh network can be set up so that data can be passed along from node to node to reach its destination, which can then be transmitted to the Internet through a base station with a wired, wifi, or cellular Internet connection. The ability to hop from node to node allows for data to be transmitted over a much longer distance than regular wifi. There are also lower frequency 900 MHz Xbee transmitters for going greater distances. And Xbee communication is specifically designed to allow for low power designs that go into sleep mode, wake up when necessary, send data quickly, and then return to sleep mode to conserve power.

This is a typical prototype sensor that uses an Xbee wireless module

Put your data to work for you!

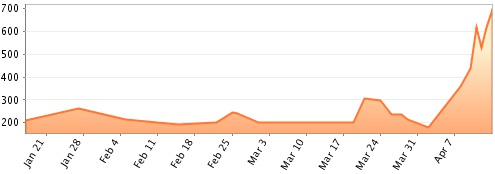

You can collect data like this...

And make charts like this!

Wireless Remote Control Do you have devices in far-away locations that need to be automatically monitored and controlled with the possibility of manual override? Save yourself the time and effort of traveling to each location to check up on things by having an Arduino do it for you over a wireless connection!

Some examples of the possibilities include:

Here's how we've helped other clients harness the power of Arduino Wireless Networks. You could be next!

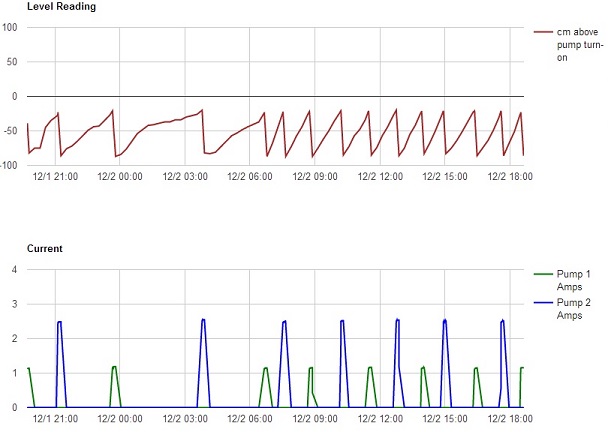

Case One - Sewage System Monitoring A county housing authority needed to monitor the functionality of their sewage holding tanks and pumps. The county had experienced issues in the past with their systems malfunctioning, which resulted in sewage overflowing from holding tanks. This was, of course, a very messy situation which resulted in complaints, costs for cleanup, and the potential for fines from the EPA. Feldman Consulting Enterprises, LLC set up systems to monitor the pumps with current clamps and sewage levels with ultrasonic sensors at two of the housing authority's sewage tanks. The readings were transmitted by the sensing unit every 15 minutes to an online database over a cellular Internet connection. The database allowed for the authority to be alerted by email very quickly when problems were detected and to resolve issues while they were still minor before they had become major disasters. The monitoring system also helped detect several other anomalies, some of which were the result of errors made during the initial setup of the sewage tanks years prior and had gone undetected ever since. Results:

Ultrasonic sensors measure the sewage level while current clamps monitor pump current. All the data is transmitted to an online database for easy monitoring at a glance.

Case Two - Stream Depth and Flow Measurement using eTape™ A local municipality needed to monitor the depth and flow rate of a stream at a remote location to ensure that enough water was being released from their reservoir into a nearby lake. By precisely measuring the depth of the stream the flow rate through a V-weir could be calculated. Feldman Consulting Enterprises, LLC set up a battery-powered remote sensing module using an Arduino and a brand new patented technology called eTape™ from Milone Technologies. This allowed us to measure the depth of the stream to within 1mm (1/25th of an inch). The readings were transmitted by the sensing unit every 15 minutes several hundred feet wirelessly via Xbee to the nearest available location with power where a cellular base station could be installed to send the reading to an online database. Results:

The sensor is mounted in the stream right in front of the V-weir, sending measurements wirelessly back to a cellular base station several hundred feet away.

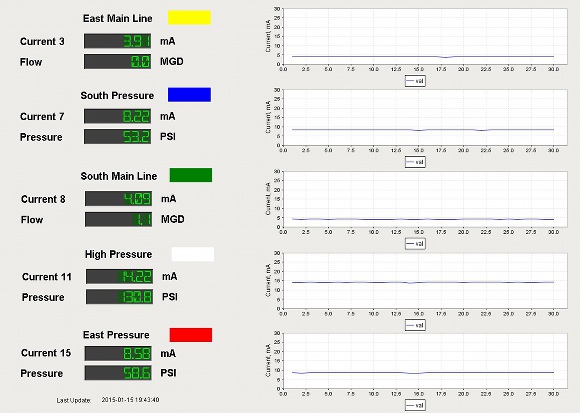

Case Three - Monitoring Water Pressure and Flow from Traditional 4-20mA Sensors A local municipality was monitoring the water flow rate and pressure through several different lines at a switching station. This installation was using traditional PLC and SCADA equipment to monitor industry-standard 4-20mA sensors that had been in use for quite some time. The goal was to read these sensors using Arduino-based technology to determine the feasibility of replacing the traditional PLC equipment with Arduino-based technology with a printed circuit board that was no bigger than a typical slice of pizza. Feldman Consulting Enterprises, LLC designed a custom printed circuit board that would simultaneously measure current from up to 16 sensors plus 7 analog signals and 3 digital signals. Since this installation had power available the data was sent directly over Ethernet to a cellular base station for insertion into an online database. Results:

This is the original PLC cabinet with all the traditional equipment.

This is a screenshot of live data obtained with the Arduino board.

Case Four - Monitoring Water Level at a Reservoir - Our Biggest Dam Project Yet! A local municipality monitors the water level at their reservoirs to determine the amount of water available and to ensure the safety of their dam. Over time the water level might vary by as much as 30 feet. These reservoirs are often in remote locations. Feldman Consulting Enterprises, LLC set up two ultrasonic sensors to measure the water level in one of the reservoirs at 15-minute intervals. The readings were transmitted by the sensing units every 15 minutes wirelessly via Xbee to a cellular base station, which transmitted the readings to an online database. The ultrasonic sensing units were about the same size as a typical coffee mug and much less complex to operate and install than the traditional vibrating wire piezometers that are often used with a SCADA system to measure water depth. Results:

The reservoir and dam

An ultrasonic sensing unit with an Arduino Pro Mini and Xbee inside - the size of a coffee mug

Case Five - Tank Telemetry Sensors A prospective client contacted us as they have a business that involves filling tanks with their products for customers in a multi-state region. Their customers used their product at different rates, and filling the tanks involved sending a truck. The client desired a tank monitoring solution that would ensure that the clients would not run out of product, but also that they didn't incur unnecessary expenses by making extra deliveries. Commercial solutions were available but they had incredibly high monthly telecommunications fees and a lot of the client's sites were in remote areas where cellular communication was unreliable. A tank level monitoring system based on the ATMega328 used by the Arduino was developed that solved all the problems the customer had. Data from multiple tank sensors at one location was bundled through one communications base station using inexpensive Xbee modules to reduce telecommunications costs because many customers had multiple tanks at their sites. In addition, several different communications base stations options were offered to eliminate reliance on the cellular networks. The tank sensors were designed with very low power consumption in mind for an expected battery lifespan of three years. Manufacturing costs were kept very low so that the upfront costs were competitive with existing offerings. The data from the sensors was fed into an online SQL database, eliminating any IT setup for the end customers and allowing for analysis and integration of the data into any systems in the future. Results:

This is a prototype of the electronics for one of our tank level sensors.

Case Six - Monitoring Pressure at a PCB Production Facility A Fortune 500 company involved in making printed circuit boards for aerospace and defense applications needed to measure pressures and other parameters at various points on their lines throughout the production process. Feldman Consulting Enterprises, LLC designed Arduino-based monitoring boards to measure many different parameters and display the values in real-time to operators on a screen. In addition, these values were transmitted to several base stations throughout the plant, which connected to an internal database over WiFi to log the data that was collected. Results:

Case Seven - Monitoring Cutting Blade Forces in a Factory A large company used machinery in production to cut material into shorter fibers. These machines had specialized blades that would get dull over time and need to be sharpened or replaced. There were strain gauges attached to the blades and there were readouts and alarms on the machines to detect if the blades failed, but there was no good way to monitor the condition of the cutting blades over time. Feldman Consulting Enterprises, LLC designed Arduino-based monitoring boards to monitor the cutting forces on the blades over time and log them into a SQL database so that the results could be analyzed and the conditions of the blades could be assessed so that it was easier to determine when they needed to be replaced or sharpened, reducing unplanned downtime. Results:

Feldman Consulting Enterprises, LLC can develop your Arduino-based solution involving Xbee wireless communication to get your data where it needs to be!

Arduino Robotics Consulting

Your project could be a Breakthrough! Contact us today to find out how! Feldman Consulting Enterprises, LLC has worked with clients all over the world and is based out of Macungie, PA. Phone: 484-695-5651

(c) 2025 Feldman Consulting Enterprises, LLC |